- Company

-

- RTHTHHTHTHATelescopic Handlers

- Paved surfacesTelescopicVertical mast lifts

Capacity

6000 Kg

Height

51 m

Engine Power

175 kW

Home > Prodotti > Sollevatori telescopici > RTH > 6.51

6.51

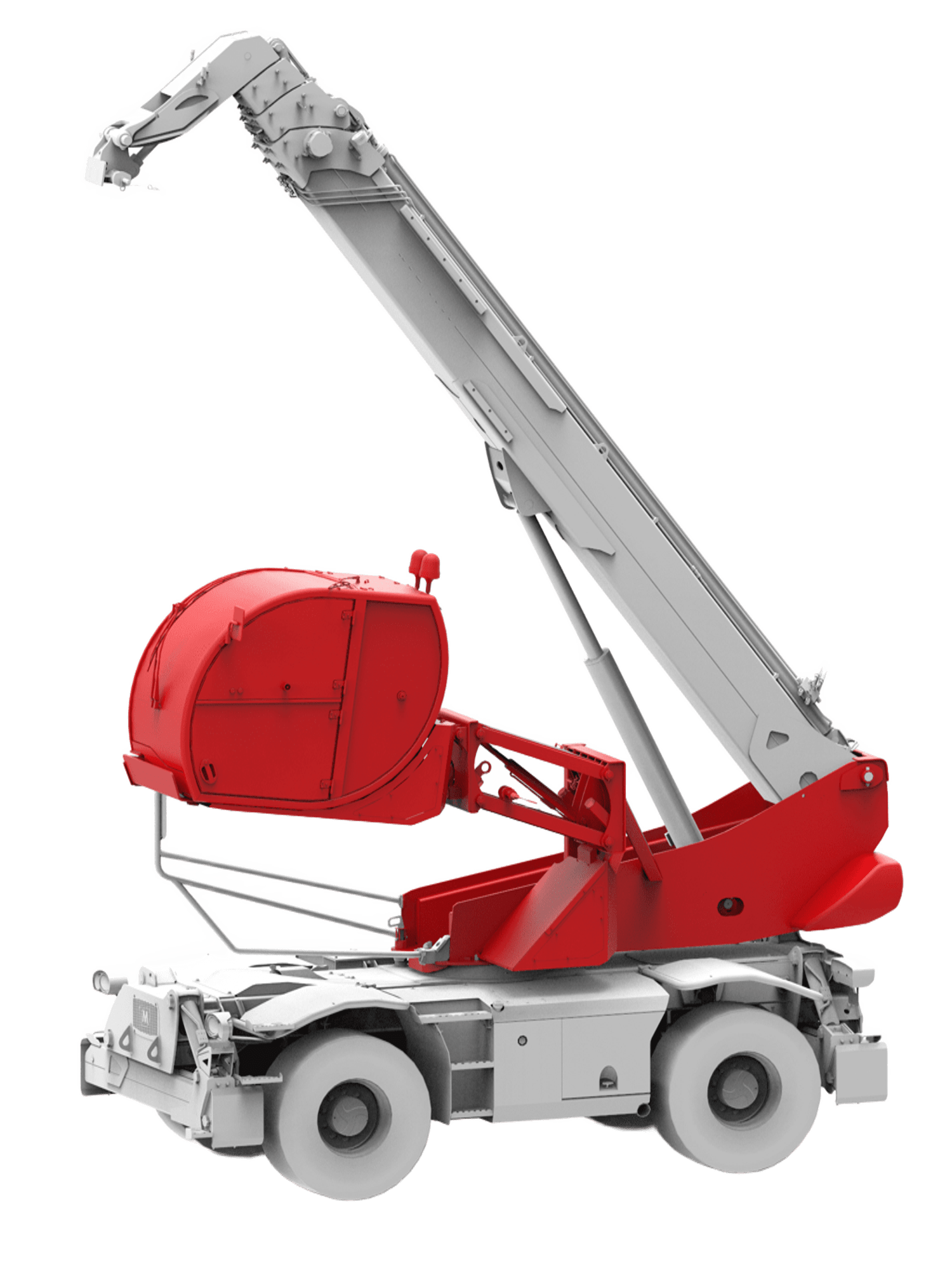

The RTH 6.51 model is the tallest rotating telescopic handler in the world. It reaches a lifting height of 51 m, ensuring a maximum capacity of 6 tons. It is the perfect solution for all those construction sites or industrial sites that require very significant reach and lifting capabilities.

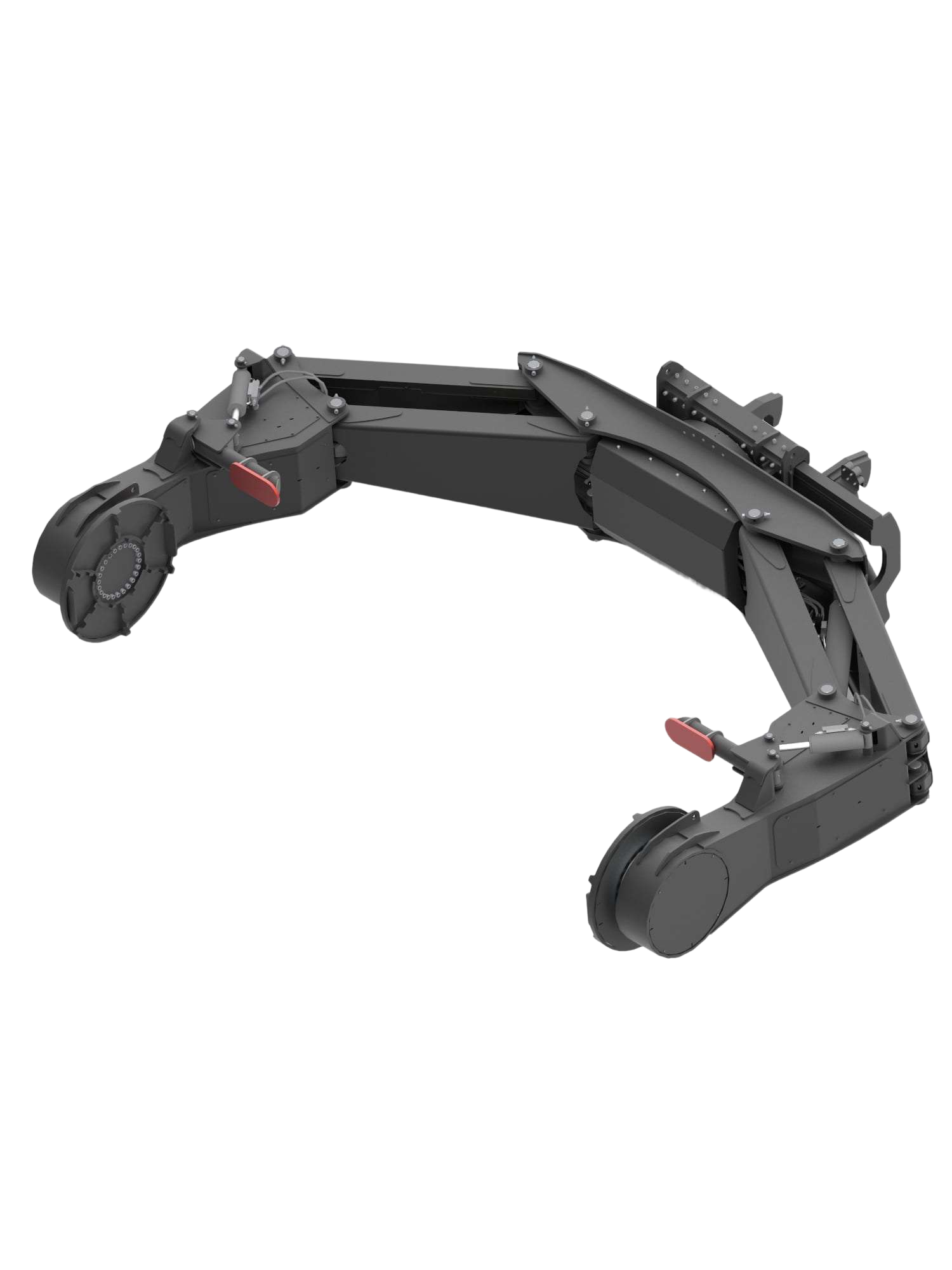

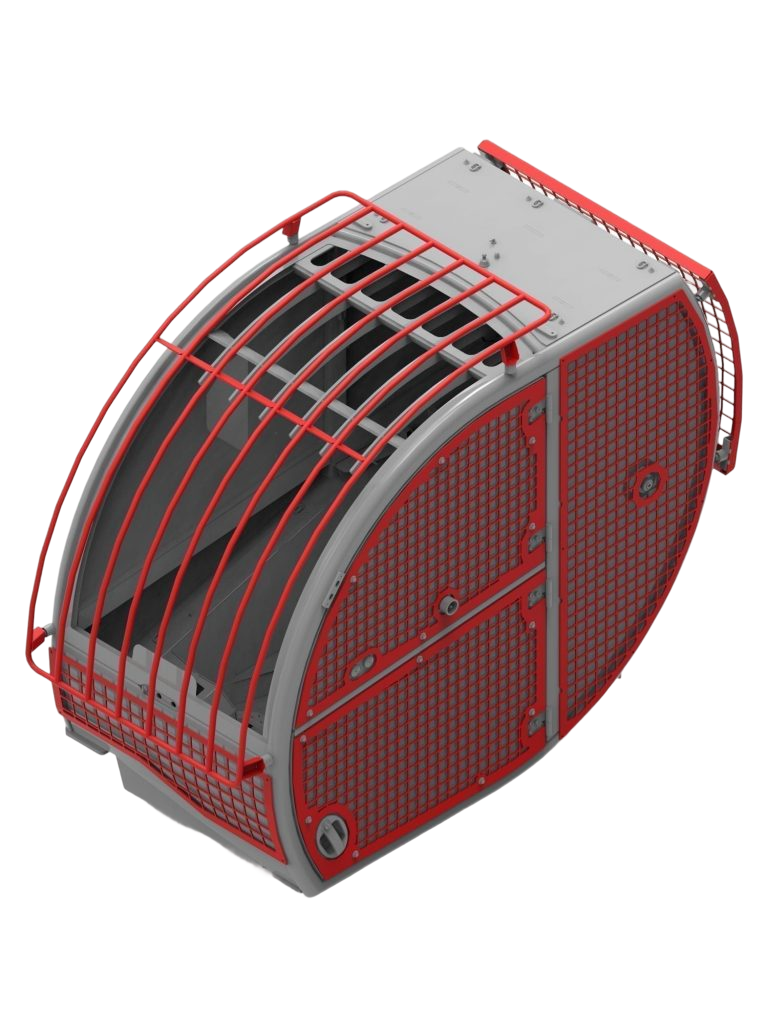

For operator safety, the tilt corrector and scissor outriggers with wide support pads offer excellent stability in all circumstances, ensuring perfect adherence on any type of terrain. The double-extension scissor outriggers are optimal even in confined spaces; even if partially stabilized, the machine is programmed to guarantee the best possible load diagram on each side. When fully extended, the outriggers ensure optimal machine performance over all 360°, being able to work on a much wider stabilization base.

This model offers the possibility to work with the same attachment in two different modes: strength mode M2 and stability mode M1. The first allows me to load very heavy loads but with a more limited reach. Conversely, the second option allows for reaching more significant outreaches with a lighter load. Compatible with a wide range of attachments, thanks also to the RFID system that allows for automatic recognition and the consequent creation of dynamic load diagrams, this handler is capable of responding to countless applications in the construction and industrial sectors.

The 6.51 is extremely versatile as, by simply changing the attachment, it can be used as a telescopic handler with forks, as an off-road crane by mounting the winch, and as an aerial platform thanks to the basket. Moreover, through the RFID system, the machine recognizes the attachment and automatically sets the appropriate safety devices and the related load diagram.

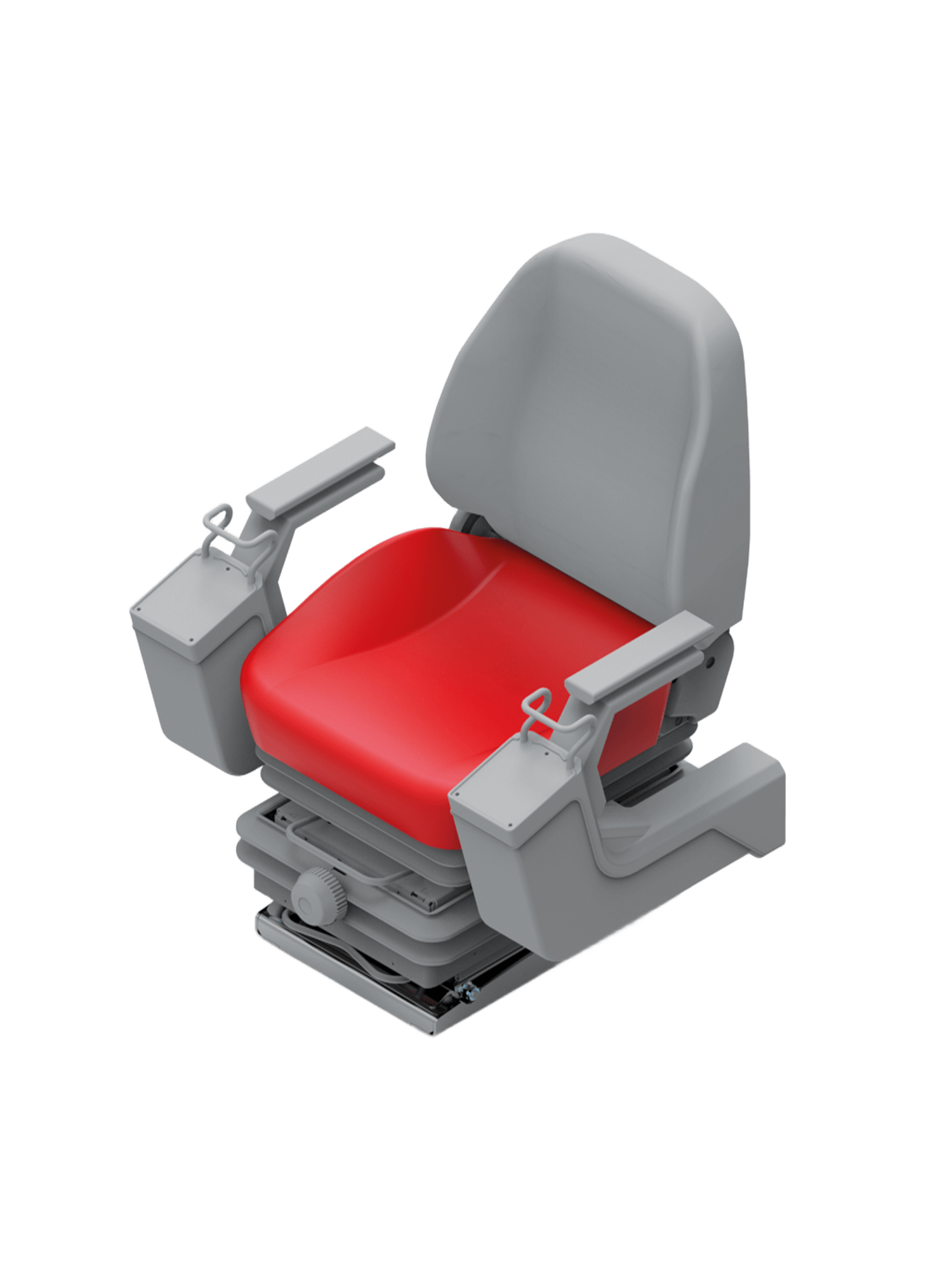

With ROPS/FOPS Level 2 certification, the cabin ensures top-of-the-class safety during all work phases.

Visibility is also improved, while maintaining all regulation and safety standards, thanks to the forward positioning of the cabin, the increase in glass surface in the upper part, and the thinning of the steering column.

The new “easy access” system, patented by Magni, facilitates entry and exit from the cabin by allowing a slight misalignment between the turret and the chassis, making it easy to access the machine.

In line with all other RTH and TH models, the cabin interiors have been completely redesigned and all coverings have been created with injection molding for greater durability and better finishes. When the door opens, courtesy lights located at various points inside the cabin turn on. These LEDs are dimmable and gradually decrease in intensity once the machine is turned off.

The airflows inside the cabin have been improved to optimize defrosting even in the coldest climates.

At the top, above the operator’s head, a standard sun shade has been positioned, lockable in two different positions to ensure maximum comfort even during the sunniest days.

It is possible to lift both armrests, which follow the seat, in order to create a practical storage pocket, housed under the right armrest. A premium seat with headrest, tilting movement, and pneumatic suspension is also available.

Accessible through the touch screen, the software has been completely renewed. The graphic restyling of the interface promotes easy and intuitive use with recognizable functions through user-friendly icons.

Unlike the previous software, a main menu page is now available from which you can access different thematic pages, with new functions that allow for a smoother and more enjoyable user experience.

Among the main features and innovations we find:

- Handling mode: which allows separating the boom speed from the traction speed, enabling more precise and faster movements when using the boom extension and wheel travel simultaneously.

- Dedicated pre-settings: three new mappings selectable by the operator, from the most precise to the most responsive, to optimize the performance of the attachment used.

A further and important innovation concerns the introduction of the Magni LLD (Live Load Diagram) system, which allows for three different types of load diagram pages and keeps maneuvering limits under control, to operate in total safety:

- Standard, which allows viewing all load ranges (also present in previous versions);

- Dynamic, which allows viewing the available work area depending on the load being lifted.

- 360° Dynamic, which allows viewing the available work area from above, ensuring greater precision when operating in non-uniform stabilization conditions.

It is also equipped with a standard rear-view camera, viewable within the MCTS monitor, which activates automatically when reverse gear is engaged.

Regulations2006/42/EC EU Machinery Directive

2016/1628 EU Regulation on Stage V engine emissions

EN 1459-X Relativa alle norme sui requisiti di sicurezza dei carrelli a sbraccio variabile

EN 280-1/EN 280-2 Norme relative alle piattaforme di lavoro mobili elevabili (se disponibili)

ROPS/FOPS Level 2 Relating to the standard for protective structures

Home > Prodotti > Sollevatori telescopici > RTH > 6.51

Technical Data

MetricoCaratteristica Metrico Imperiale Stabilizers A forbice A forbice Lifting Capacity 6000 Kg 13200 lbs Maximum Height Capacity 2000 Kg 4397 lbs Lifting Height 51 m 167' 4'' Max reach 34.50 m 113' 1.97'' Engine Volvo TAD 583 VE - Stage V Volvo TAD 583 VE - Stage V Rated Power 175kW 238hp 2.300rpm 175kW 238hp 2.300rpm Travel - - Hydraulic Flow Rate - - Number of Gears 2/2 2/2 Hydraulic system 350 bar Load Sensing - Length 10.33 m 33' 10.97'' Width 2.54 m 8' 4'' Ground Clearance 340 mm 1' 1'' Unladen Weight 36300 Kg 80030 lbs Speed 40 km/h 25 mph Rotation 360° Continua 360° Continua Standard Air Conditioning Yes Yes Automatic Attachment Recognition Yes Yes Reversible Fan Yes Yes Compatible accessories

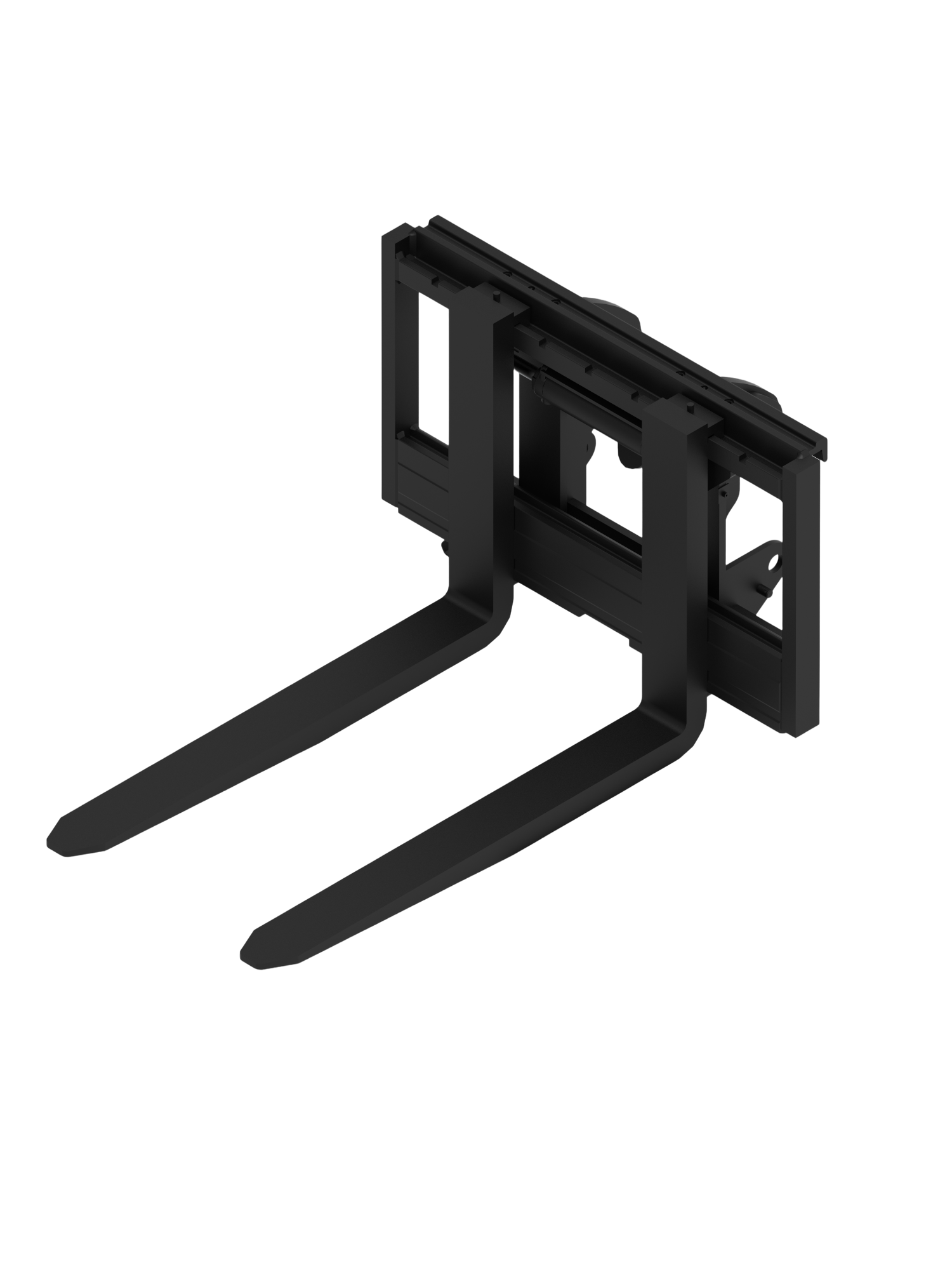

Forklifts

Special

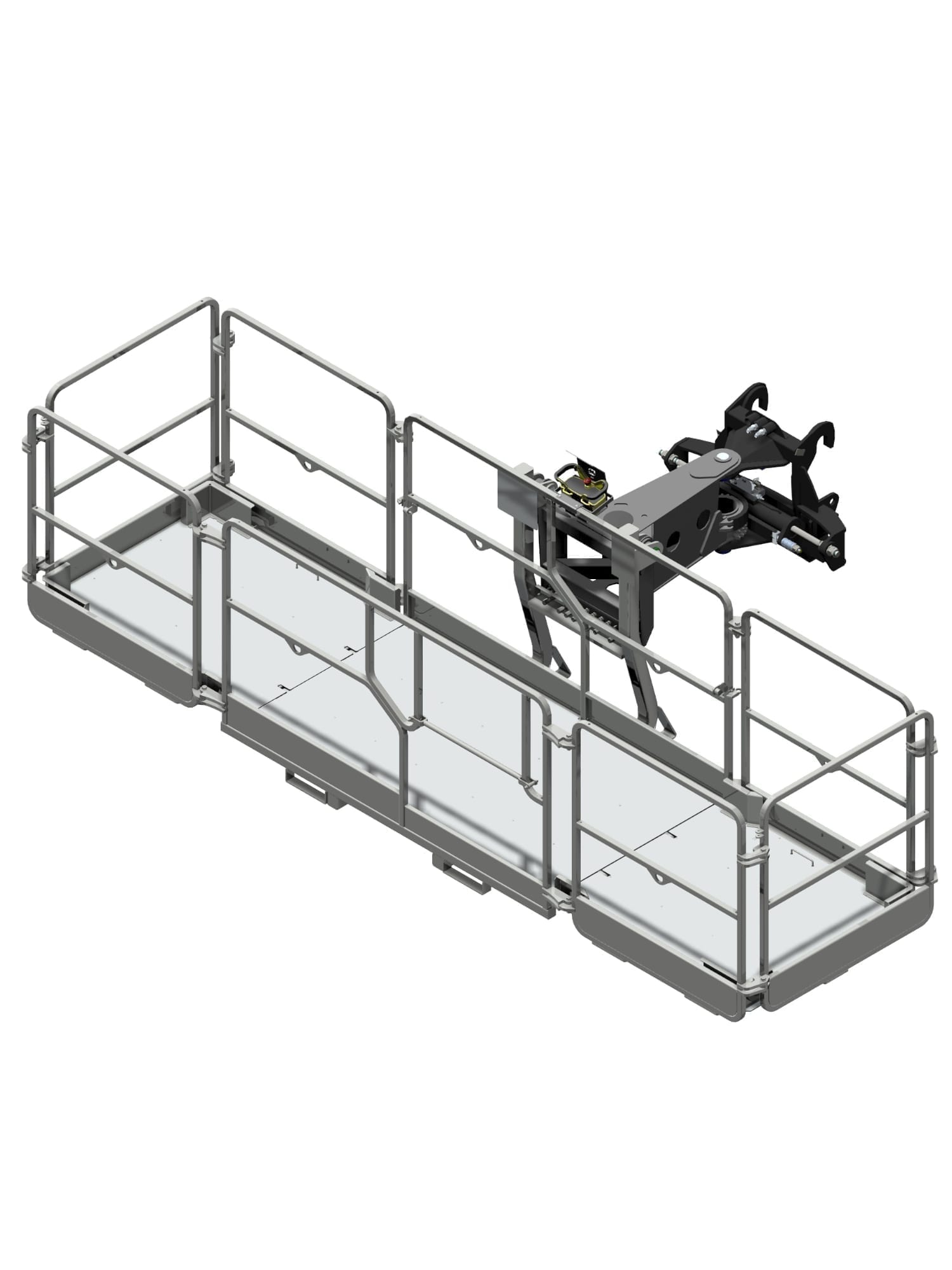

Platforms

Hooks

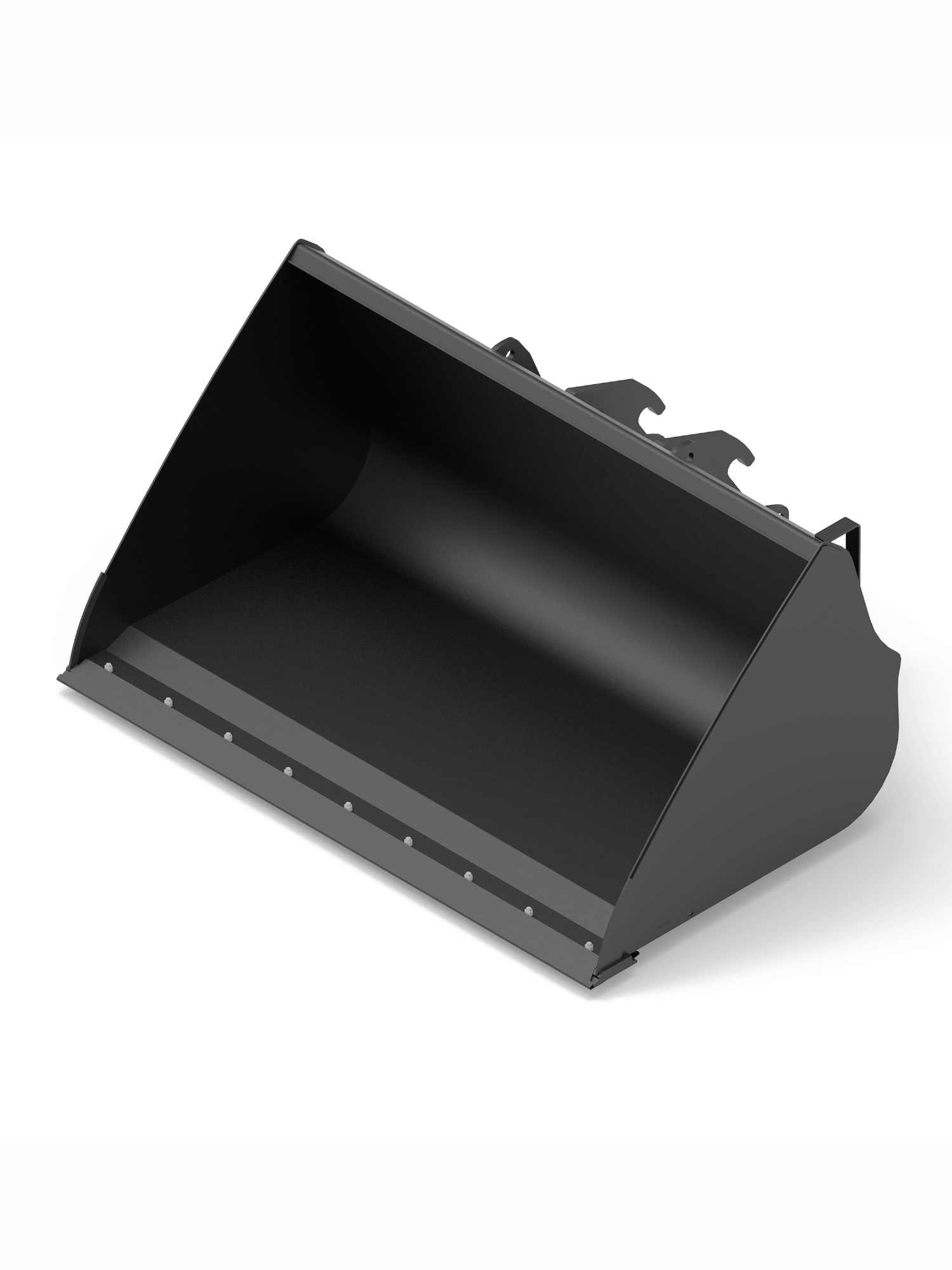

Loaders

Grippers

Booms

Winches

Optional

Setups and Certifications

Comfort

Performance

Safety

Specials

Discover our dealers

Do you want to find a Magni dealer?

We are present worldwide through an extensive network of dealers ready to help you find solutions tailored to your needs!Request a quote

Would you like more information about our products?

Your next product is ready to be ordered.

Choose what suits you and send us a quote request.

Our team will be happy to address your needs.What's new at Magni

Subscribe to Magni’s newsletter! You will periodically receive updates and the latest news from the Magni world via email.

MAGNI TELESCOPIC HANDLERS SRL SINGLE-MEMBER COMPANY Via Magellano, 22, 41013 Castelfranco Emilia, Modena | T: +39 059/8031000 | E: commerciale@magnith.com | VAT No. 03353620366 | SDI R7Y4CEC

- Website Privacy Policy

- Terms of Use

- Cookie Policy

- General Terms of Sale

- Whistleblowing

- Accessibility